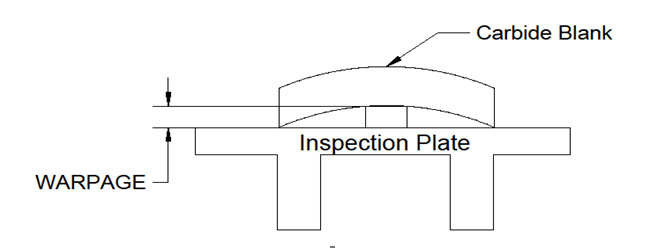

Because of the part shrinkage associated with sintering (about 20% for any dimension), it is typical for the carbide blanks to have some warpage. All blanks manufactured by Carbide Technologies are put through a straightening process and straightened to the degree that the remaining warpage will “clean up” as the grind stock is removed during the customer’s finishing process.

Carbide Technologies uses one of two basic processes to measure warpage and determine that the manufactured blank will “clean up” in the customer’s process.

All measurements are indicated in inches.

Blanks with a single OD, Rod, and Rectangular Blanks are checked on a flat inspection plate. At the point where maximum distance occurs between the plate surface and the blank, a feeler gauge is used to measure warpage. Maximum warpage allowed is based on the OAL/OD grind stock as shown in the following chart:

| Blank OAL | Max. warpage |

| 3.000 or shorter | .006 |

| 3.001 – 11.999 | .007 |

| 12.000 or longer | .008 |

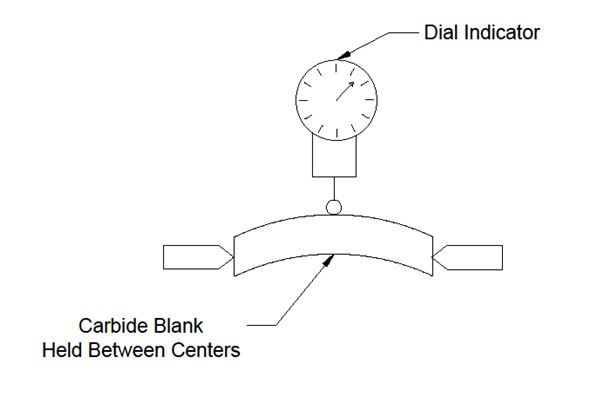

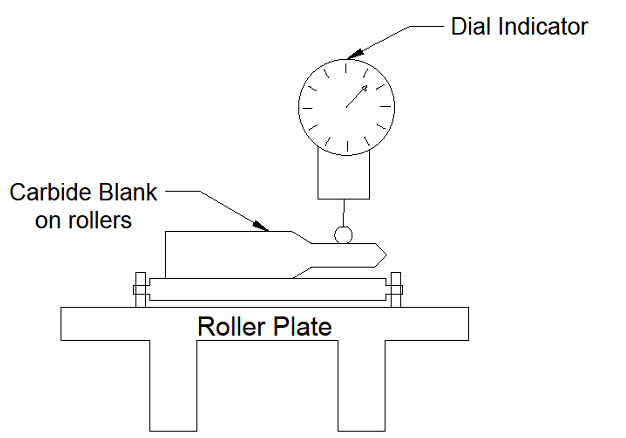

Blanks with Multiple OD’s are checked on a center fixture or roller plate with an indicator. TIR (Total Indicator Runout) is determined by placing the indicator at the point of maximum runout and measuring the total warpage as the blank is rotated. Maximum TIR allowed is based on the OAL/OD grind stock as shown in the following chart:

| Blank OAL | Max. TIR |

| 3.000 or shorter | .012 |

| 3.001 – 11.999 | .014 |

| 12.000 or longer | .016 |